Fengxiang Vegetable Salad Processing Line for Cutting, Bubble Washing, Dehydrating

OEM/DOM-baking series, processing series, egg roll series, biscuit series, net red food series

Product Classification:

Key words:

- Product details

-

Salad Processing Line with Vegetable Washing Machine Product Overview

Product Description

The salad processing line is designed for efficient, hygienic, and large-scale preparation of fresh-cut vegetables and ready-to-eat salads. Integrated with a high-performance vegetable washing machine, this line is widely used in central kitchens, fresh food factories, salad producers, and food service suppliers that require stable output and strict food safety control.

By combining cutting, multi-stage washing, disinfection, and centrifugal dehydration into one continuous workflow, the salad processing line helps processors reduce labor costs, improve consistency, and meet international hygiene standards.

Application Scenarios

This salad processing line is suitable for:

Central kitchens and catering supply centers

Ready-to-eat salad and fresh-cut vegetable factories

Supermarket vegetable processing centers

Food export processing plants

Typical raw materials include lettuce, cabbage, spinach, celery, carrots, onions, and mixed leafy vegetables.The Specification of Vegetable Salad Processing Line

Machine

Dimension

Voltage

Power

Capacity

FC-306L cutting machine

1020*760*1370mm

220V/380V

1hp+1/2hp

1500-2000KG/h

Elevator

2520*740*1950mm

380V/50(60)HZ/Phase

0.25 KW

500-1000kg/h

WA-1000 washing machine

2500*900*1140mm

380V

3.2kw

500-700kg/h

Continuous dehydrator

1380*1380*1850mm

380V

2.4kw

300-500kg/h

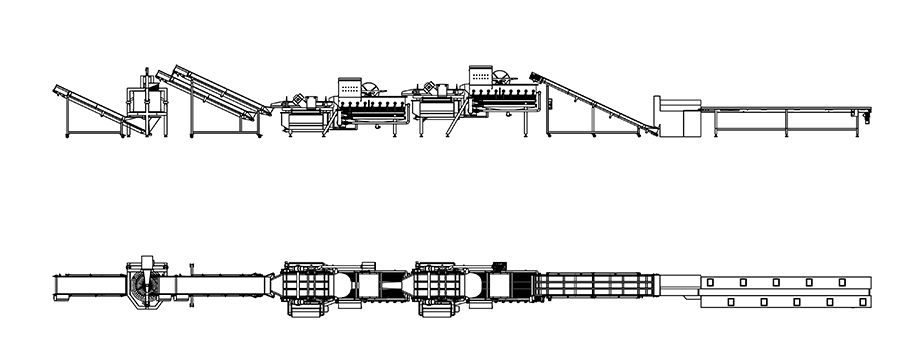

Vegetable Salad Processing Process Flow:

Vegetable Cutting → Lifting and feeding (to the vegetable washing machine) → Washing and decontamination → Secondary cleaning → Lift and transport (to the dehydrator)→ Dewatering → Final outlet with conveyor

1) Vegetable cutting machine: It is used to cut vegetables into slices, chop and shred, with a large output and adjustable cutting thickness.

2) Funnel elevator: It is used to lift leaf vegetables and connect with the vegetable washing machines.Adjustable belt tension and easy to clean.

3) Vegetable washing machine: The combination of three cleaning methods, such as air bubbles, circulating surfing and high-pressure spraying, is used to thoroughly clean the vegetables in all directions.

5) Continuous dewatering machine: It uses the principle of centrifugation to dehydrate and dry the material to remove the moisture on the surface.

6) The production line can be customized, automatic and simple operation, in line with food safety standards, suitable for Small and medium-sized catering enterprises, etc.Details of Vegetable Salad Processing Line

The whole salad production line can be customized according to your needs.

Cutting and Pre-Processing Unit

Vegetables are evenly cut into slices or strips according to processing requirements. Cutting size can be adjusted to match different salad recipes and packaging standards.

Vegetable Washing Machine System

The Integrated vegetable washing machine adopts bubble washing technology combined with water circulation filtration. Gentle air bubbles and controlled water flow effectively remove soil, sand, insects, and pesticide residues without damaging delicate leaves.

Dehydration Module

After washing, the centrifugal dehydrator removes excess surface water, improving shelf life and preparing the product for downstream packaging or mixing.

►The finished vegetables are dry and undamaged, processing effect is good.

FAQ – Salad Processing Line & Vegetable Washing Machine

Q1: What types of vegetables can this salad processing line process?

A: It is suitable for leafy vegetables, root vegetables, and mixed salad materials such as lettuce, cabbage, carrots, onions, and spinach.Q2: Is the vegetable washing machine gentle enough for leafy vegetables?

A: Yes. The bubble washing system is specially designed to clean vegetables thoroughly without damaging leaves.Q3: Can the salad processing line be customized?

A: Yes. The configuration, capacity, and washing stages can be customized based on production requirements.Q4: Is this line suitable for export-oriented food factories?

A: Yes. The design follows food hygiene standards commonly required for export processing.

Keyword:

Fengxiang Vegetable Salad Processing Line for Cutting, Bubble Washing, Dehydrating

Related Products

Product inquiry

Thank you for your interest in FengXiang. You can contact us using the contact form