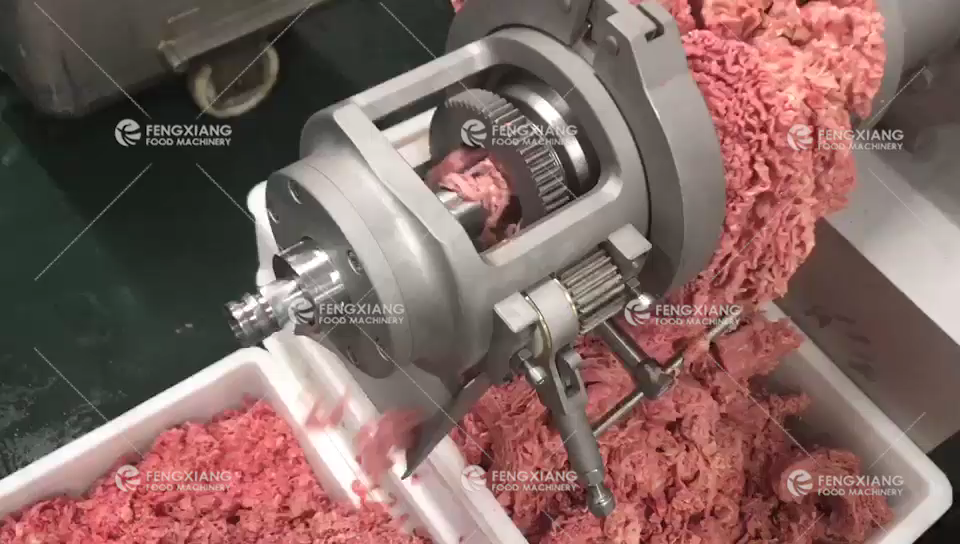

Industrial meat and bone separator, chicken bone grinder,meat and bone separator is mainly used to separate meat with bones,No any bones after separating, the paste can be processed directly.The machine can process diversified materials : fish, chicken, goose, rabbit , duck, cattle,pork bone, hammer, beef ,mutton, etc.The main product of processing - meat emulsion, can be added to meatballs, sausages and other meat products.Apply to Large and medium-sized meat processing plants, meat products factory and poultry slaughter plant.

The Specification of Meat and Bone Separator Machine

|

Dimension |

1440*630*970mm |

|

Hopper Volume |

20L |

|

Weight |

450KG |

|

Power |

6.5/8KW(two-speed motor |

|

Capacity |

300-500kg/h |

|

Configuration table |

Siemens motor(380v/50hz,3phase) |

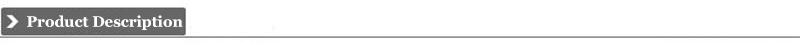

Details

Bone and meat are delivered through different outlet port

High separation rate, high meat quality and non-destructive.Good for processing meat products

The Specification of Meat and Bone Separator Machine

1. Low maintenance cost and low noise.Easy to take apart,reassemble and clean.

2. Not damage meat tissue fibers, guarantees meat content and taste,

3. The machine is made of stainless steel and meets food grade standards.

4. The mechanical separation process consists in separating meat from bones, pulping from fruits and vegetables.

5.Can reduce production costs of enterprises, and effectively prevent protein waste of resources

6.Multiple uses of one machine can save manpower, and the productivity can reach 300-500kg / h.

| FC-300 Poultry Dice Cutting Machine |

|

| Document | Download |